A 12-week project to design and build a human-powered commuter vehicle.

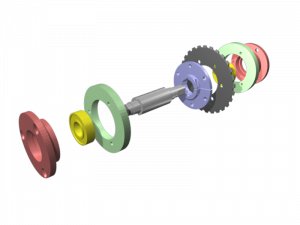

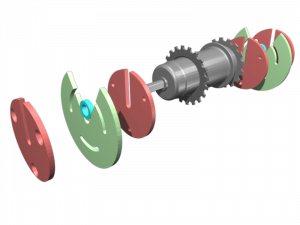

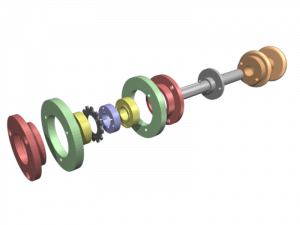

Our goal was to empower a user group that is ordinarily resistant to bicycle commuting. The solution involved a relaxed seating position that allowed the user to place his/her feet on the ground while sitting on the bike, a carbon fiber frame with an enclosed drivetrain that hid the mechanics from sight and prevented them from interfering with the legs, and one-sided forks on the front and rear that allow the user to repair a flat or replace a wheel with ultimate ease.

promotional video

process video

Design Team: Erik Askin, Mike Eng, Hemi Mansharoff, Harry Niemann, Ashley Rozier-Walker, Krisa Ryan, Nick Tomlin, Adrian Waibel

My Role: Component design, production management, welding and brazing. The enclosed drivetrain required a significant amount of custom-machined components, which I modeled in Solidworks.

Some photos below. Also, view the project blog for more.