Manual harvesting is often exploitative and dangerous. In Brazil's sugarcane and ethanol industries, from 2002-2005, 312 workers died on the job.

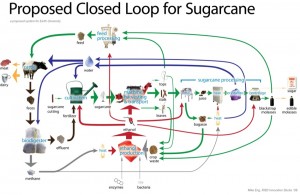

A proposal for Earth University featuring a closed-loop harvesting system with several steps involving the production of cellulosic ethanol from the waste products of the sugarcane plant.

Earth University, located in Costa Rica, aims to contribute to sustainable development around the world with an emphasis on Latin America and the Caribbean, a region known for its biological and cultural diversity, and also for being threatened by social disparities and inappropriate natural resource management. The university is dedicated to education in the field of agricultural sciences and the rational use of natural resources. Graduates earn a licenciatura degree in Agronomy. Earth exports its agricultural produce to earn income for the university while enriching the students’ curriculum with real-world business experience.

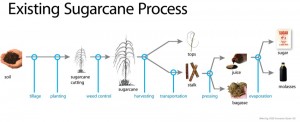

One of their exports is sugarcane, which poses a significant challenge in harvesting. Currently, there are two main methods of harvesting sugarcane, which both have significant drawbacks. Machine harvesting is energy-intensive, costly, and emits significant amounts of carbon. Manual harvesting is labor-intensive, dangerous, and often involves exploitative labor practices. Redesigning the harvesting system could solve these problems while creating new sources of fuel and animal feed from the waste products of sugarcane.

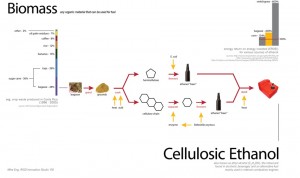

Ethanol production from sugarcane is commonplace in Brazil, where it is an abundant source of vehicle fuel. In this design proposal, the ethanol made from field waste would be used to power the sugarcane harvester.

In addition, the harvester itself is redesigned to capture the protein-rich tops of the sugarcane to be used for animal feed at La Flor. Animal waste is then put into a biodigester to produce methane, which fuels the ethanol production process. The effluent (solid waste) from the biodigester is then put back into the fields as fertilizer.

The proposed closed loop system for sugarcane harvesting, utilizing waste products from the sugarcane plant to produce ethanol.

Proposed modifications to the traditional machine harvester required to collect waste products from the cane, rather than leaving them in the fields.

Completed as part of the Innovation Studio, 2008 at RISD.